You may already know that natural gas is an abundant and affordable source of energy to heat homes and generate electricity. Did you also know that this same natural resource is used to create many of the other fuels and products that we use every day? One of the ways Williams makes the most of natural gas production is through natural gas liquids (NGLs) projects. Natural gas liquids, which are valuable byproducts of natural gas processing, are used to blend into motor fuels, heat our homes and make raw products for manufacturing a myriad of goods such as tires, clothing or other plastic goods.

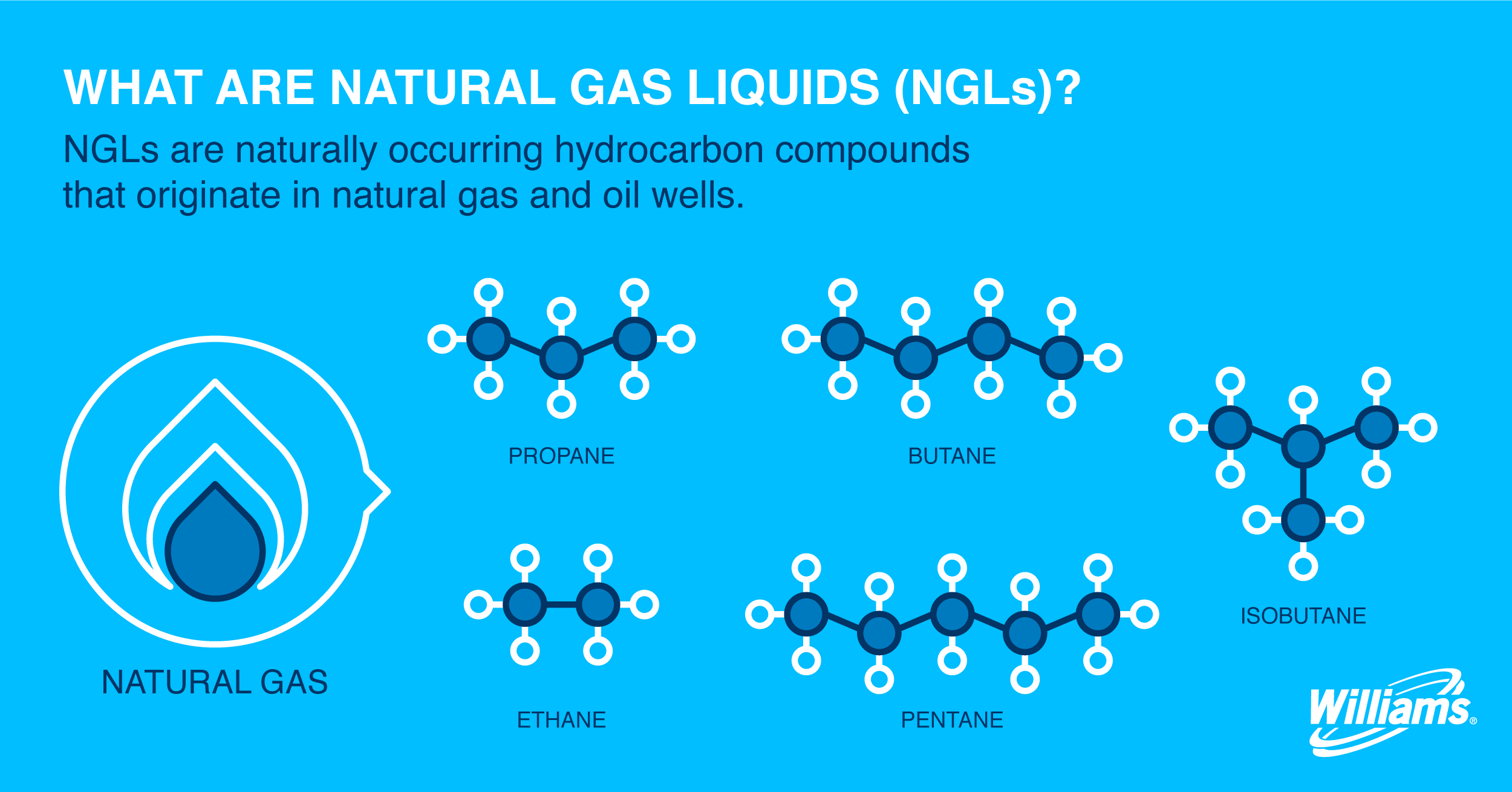

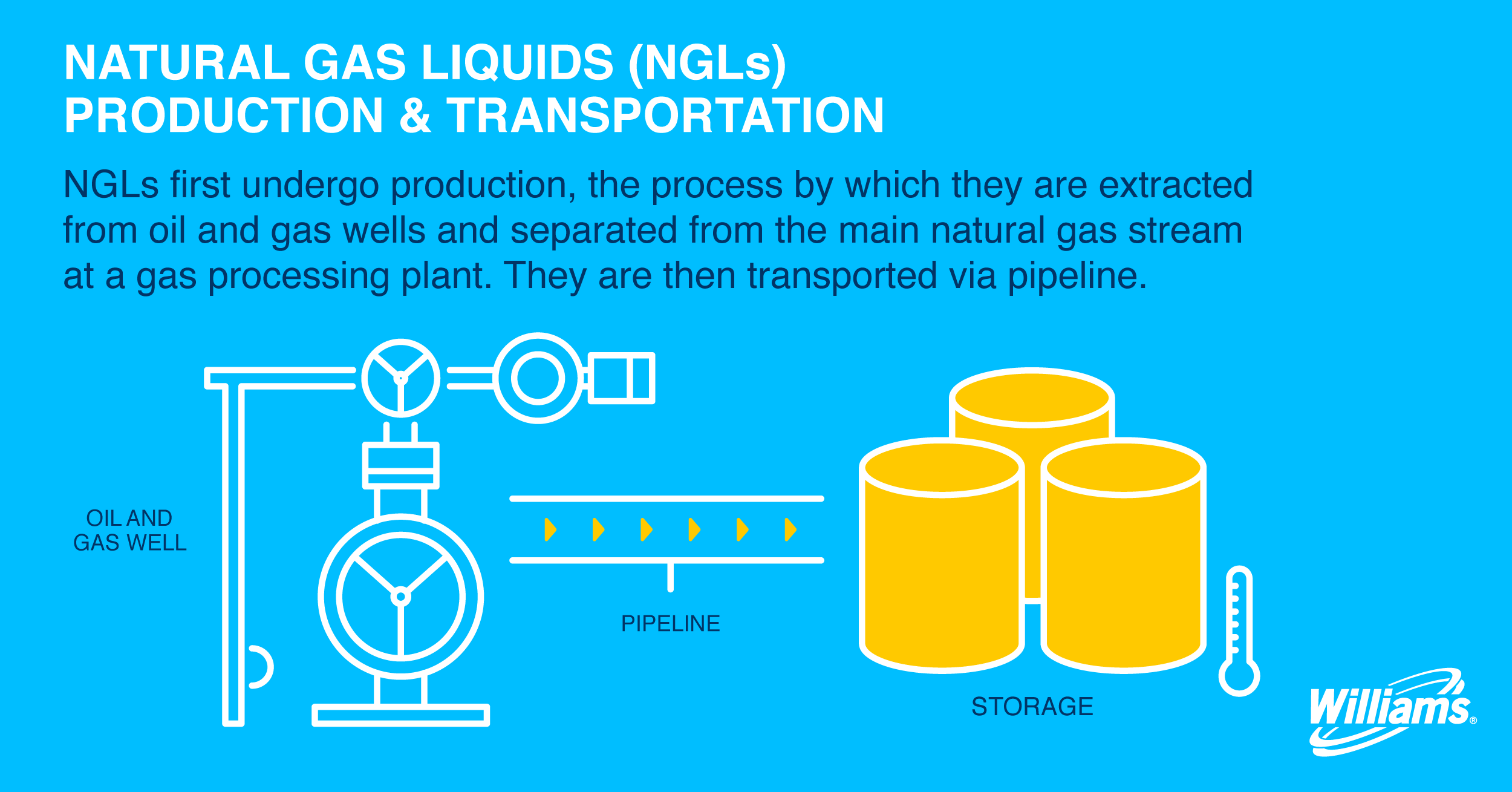

NGLs are naturally occurring hydrocarbon compounds that originate in natural gas and oil wells. Although NGLs are in the same molecular family as crude oil, NGLs are chemically simpler to extract and use. Natural gas wells produce methane (the natural gas you’re likely familiar with, typically used to heat homes) and NGLs. Essentially, we connect a pipeline to natural gas wells, draw the gas from the well, and then cool and pressurize the NGLs to separate them from the natural gas and turn them into their liquid form.

Here’s a quick refresher on basic chemistry. Matter has three states: solid, liquid and gas. Depending on the compound, a chemical can move from one stage to the next when its temperature changes. At a natural gas processing plant, natural gas liquids are extracted as liquids from a hydrocarbon stream that is in a gaseous state. Once they’re separated from the larger stream, they are transported as a mixture via pipelines to an NGL processing plant, also known as a fractionator. For example, the recently completed Williams Bluestem pipeline carries NGLs from our Mid-Continent Fractionation and Storage Facility in Conway, KS to Kingfisher, OK where it connects with other pipeline infrastructure.

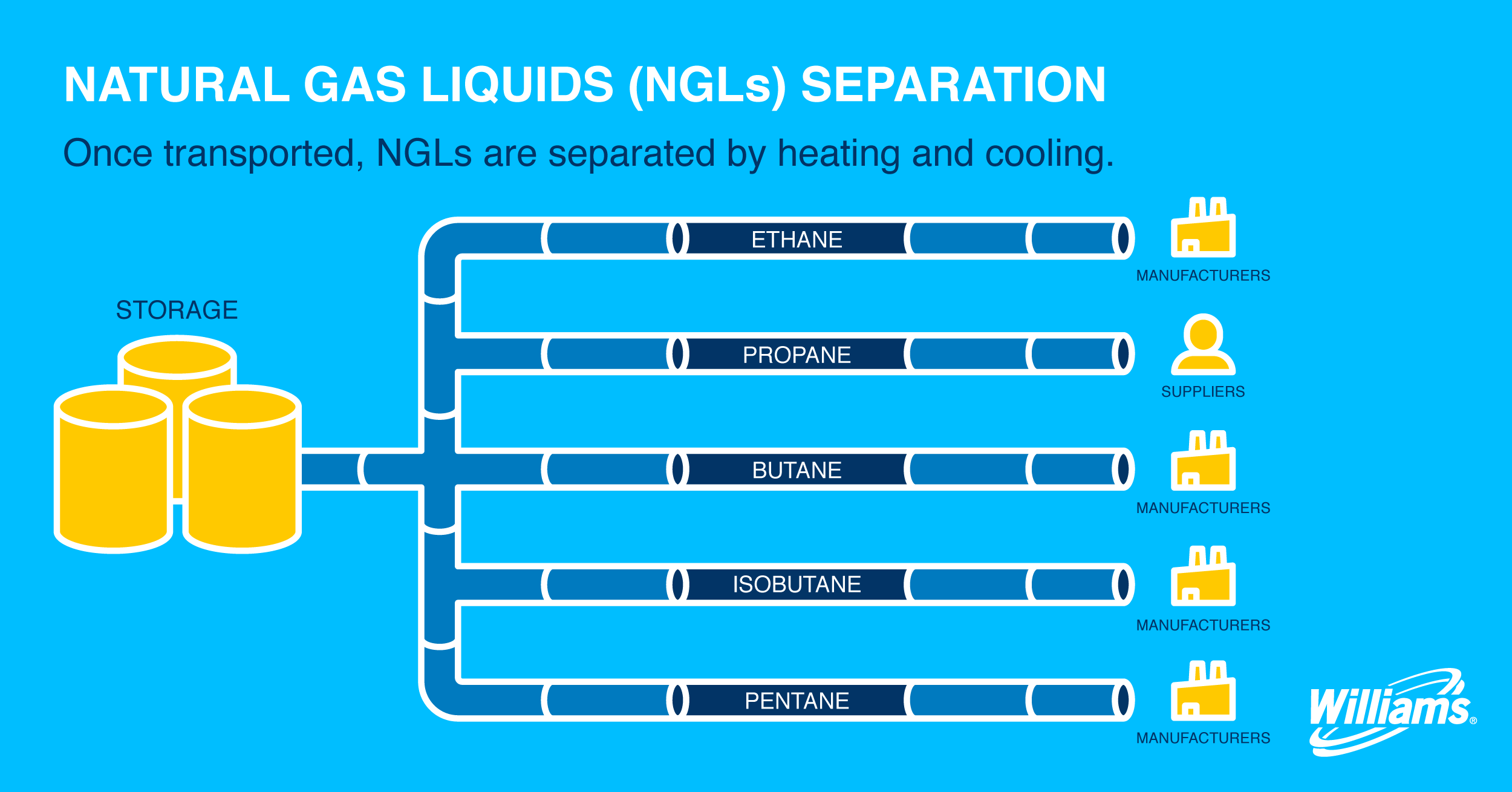

At the fractionator, the NGLs are separated from one another. Since each component has a different temperature at which it changes from gas to liquid, the separation process typically involves heating and cooling the liquids at different temperatures.

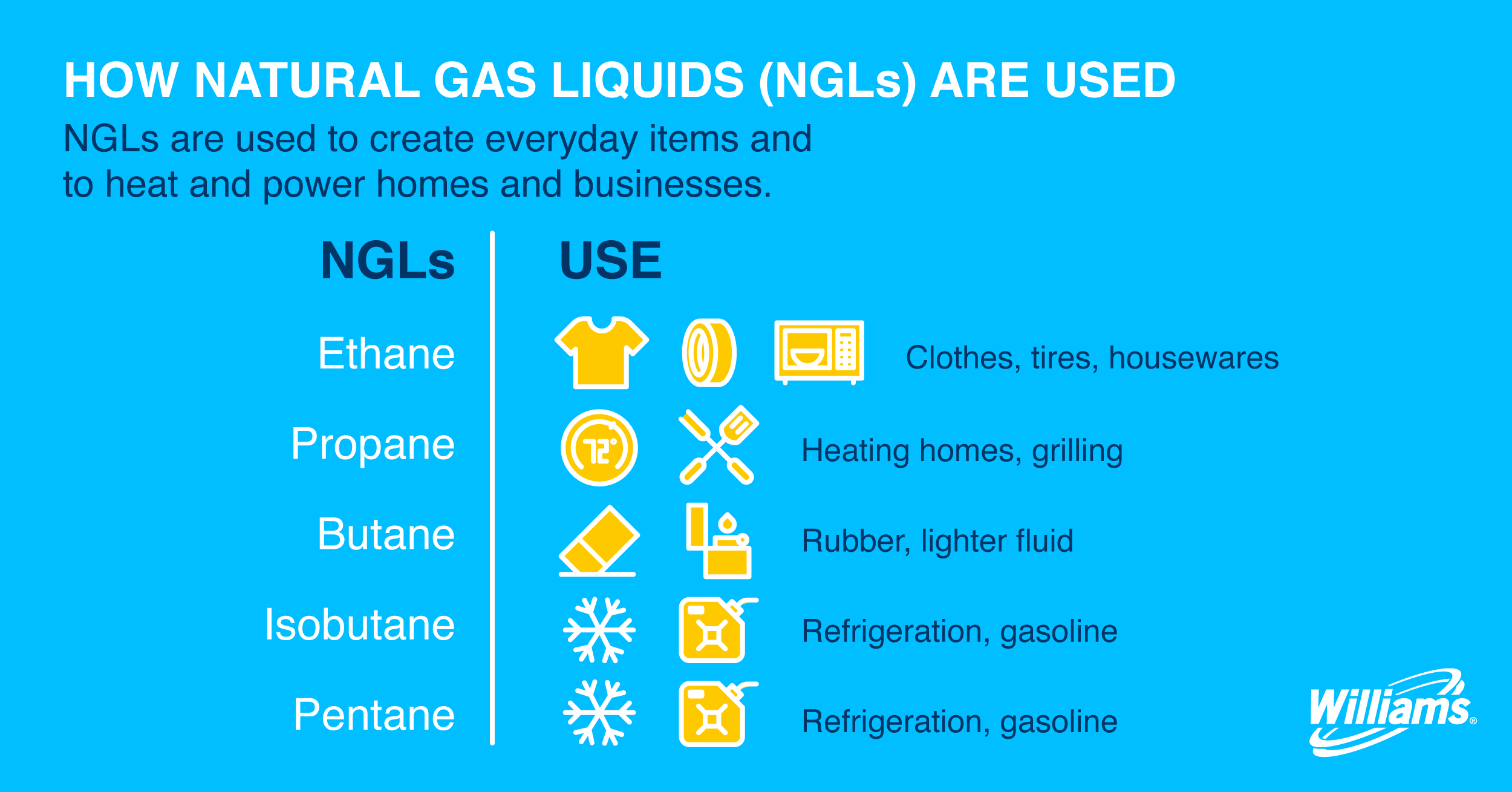

After our facilities separate out the natural gas liquids from each other, the liquids are ready to be stored, transported or used by manufacturers and gas suppliers. Williams also stores NGLs at our Conway facility, and we are one of the leading NGL storage providers in the U.S. Common NGLs that are separated out include propane, ethane, butane, isobutane, pentane and natural gasoline. Propane is used to heat homes and businesses, while ethane is used to create clothes, tires and houseware. Butane, isobutane, pentane and natural gasoline are used for refining and fuel.

But how do we safely transport NGLs? According to Pipeline and Hazardous Materials Safety Administration (PHMSA), a U.S. Department of Transportation agency, pipelines are the safest way to transport NGLs. While rare, pipelines are not immune to leaks. Williams’ strongest imperative is safety, and we employ numerous methods to evaluate and eliminate risks to our pipelines before they occur and to identify and repair leaks quickly when they do occur. We conduct 24-hour monitoring on our pipelines while also carefully monitoring and maintaining temperatures and pressure.

The greatest threat to pipeline safety is third parties digging near pipelines without proper notification and line marking. Some of our most important tools in protecting our pipelines are the line markers that are installed on all pipelines and the important outreach work that we do to raise awareness of the presence of pipelines.

The process of extracting and transporting NGLs is complex. As a company, Williams has decades of experience in the safe processing, handling and transportation of NGLs. Our personnel have the skills, training and experience to deliver on our commitment to safe pipeline operation. Because of natural gas companies like Williams and our NGL pipelines, fractionators and storage facilities, you are able to enjoy clean and safe energy that heats your homes, enables your transportation, clothes you and makes many of the other products you use safe and easy to acquire. Williams’ NGL projects help pave the way towards a cleaner environment and future.